Container Ship being Loaded; time-lapse

Container Ship

Container Ship

Malcolm McLean who began as a truck driver in North Carolina before developing a very successful trucking company, invented the idea of the shipping container in the 1930%u2019s. He came up with the idea of using the body from a tractor trailer and placing it fully loaded onto a ship or rail car, saving the hassle of unloading and reloading crates from his trucks. This idea became the basis of the Sea-Land company, the first shipping company to utilize cargo containers. His simple invention revolutionized global trade, by increasing the efficiency and ease of shipping, and creating a new standard and interchangeable unit for trade which could be easily transported by ship, truck or rail, without being unloaded..

(Via Polar Inertia: journal of nomadic and popular culture.)

Today, approximately 90% of cargo moves by container, sometimes stacked up to 12 units high on transport ships. Over 100 million containers per year are now moved between the world's ports in over 5,000 container ships, constituting a critical component of the global trade.

Last year the Port of Long Beach alone handled 4.6 million twenty foot containers of cargo and it is expected that by 2020 the port will be handling 12-16 million units.

The rise of trade between the U.S. and Asia is attributed to the reductions in cost and shipping time that containerization has made possible. For example standard shipments from Hong Kong to New York took approximately 50 days in 1970 and today takes only 17 days.

An ISO standard (International Organization for Standardization) 20 foot freight container has inside dimensions of 19‘5“ (length) by 7’8” (wide) by 7'9.5" (high) The container itself weighs 4189 pounds, and has a dry capacity of 48,721 pounds, and a volume of 1,165 cubic feet.

A standard new 20ft dry freight container costs US$1,350 and a 20ft refrigerated container $14,000.

The ISO standard shipping containers are designed to make vertical contact with eachother through corner fittings so when stacked all vertical load is carried through the corners rather than the walls of the container.

The number of containers which can be stacked is limited by the strength of the corner posts. The ISO standard tests the containers to a load of 86,400kg (190,486lbs) or the equivalent of eight containers of weight. Higher strength corner fittings can allow stacking up to 12 units high.

It is the standardization of container sizes and corner fittings by the International Organization for Standardization that was essential to the free interchange of containers and the dominance of the freight container in international trade. This standardization became possible when Malcolm McLean provided to ISO a royalty free license, allowing use of his patented designs on shipping container fittings, in the creation of an international standard which allowed other shipping companies and countries to establish a single systems of transport.

related links:

cargo systems industry magazine

[PORT OF LOS ANGELES HISTORY](http://www.laporthistory.org/level4/port_history/port_trend2.html)books for additional information:

[the colombo bay](http://www.amazon.com/exec/obidos/tg/detail/-/074320073X/qid=1078602833/sr=1-1/ref=sr_1_1_xs_stripbooks_i1_xgl14/002-8195857-8608003?v=glance&s=books) by richard pollakFreitag Recycled Shipping Container Store in Zurich

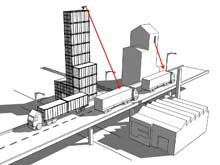

It's impressive to see just how much the Freitag brothers and their namesake corporation are into reusing and recycling materials that would otherwise be abandoned. We recently found out about their flagship store in Zurich (Maybe some of our Swiss readers have seen it? You can leave your impressions in the comments): It is made out of “used Type 20/8/86 ISO1CC Type Steel Dry Containers”, reminding us a bit of the shipping container house. “Optimum use had to be made of the small plot of land right next to Gerold-strasse. The standard 20-foot shipping container was chosen as the basic building block for the construction of an asymmetric tower of 9 containers rising from a 4 x 2 base. Set back from the road, the structural shell of the building emphasizes the size of the adjacent brownfield site. The base is used as a sales outlet, while the tower has become a striking landmark between two main international transportation routes. The circle, from product to building to product, is complete.” More below.

(This post continues on the site please click the title)

(Via Treehugger.)

17 containers for a concept store

Last month, the buzz in the design/architecture blogosphere was echoing the opening of the new "Freitag Individual Recycled Freeway Shop", a 26 meter high concept store in Zurich. The store is built with 17 rusty, recycled freight containers. On the top is a telescope to do some truckspotting and a panorama plate (designed by Yves Netzhammer) which illustrates what is on view.

So far the reactions of passersby in Zurich have ranged from irritation to curiosity: “Does it really last?” "I want to go up there!“ ”No, I am acrophobic!"

I couldn't find enough information online to satisfy my curiosity so i asked a few questions about the container structure to Daniel Freitag who created the recycled bags empire together with his brother Markus (photo).

Who and how did you get this idea of using containers?

Freitag bags are made of used truck tarps, bicycle innertubes and car seatbeltss. Hamburg is one of the biggest logistic Mecca of Europe - the perfect location for a FREITAG flagship shop. Inspired by the trucks and the harbour, we placed a 40" Container (artificial) into our shop-location. For the shop concept in Zurich we took it one (or even two) steps further: an entire building assembled from 17 used freight containers.

The idea of the tower is inspred by the history of Freitag. Freitag was born in the student-flat of my brother Markus. He used to live next to the same freeway where the Freitag shop is located. The view out of his kitchen-window onto 24h Truck-traffic inspired us to produce bags from used tarps.

See drawing below, left.

**

Isn't it dangerous to move inside the containers? How do you go from one level to the other? How do you bring light inside the containers?**

There is a staircase to climb to the shop levels and to the tower. The construction respects the Swiss norms, it's therefore very safe! There are four big windows and a glass-entry, so it is not dark at all. The building is isolated by Foamglas (made from recycled glass) to ensure that temperatures are comfortable both in the Winter and in the Summer.

**

Is it a permanent installation? Do you plan to install similar constructions elsewhere in the world?**

The shop is planed to stay for 5 up to 10 years - it was a great challenge, but also great fun to realise this project. It is to early to say if we will open similar shops elsewhere in the world. But I would not say “no”…

Thanks Daniel!

A few other names should be mentionned: Spillmann.echsle architekten eth, Zurich and the realisation team from Raumbau, Zurich.

Images courtesy of Daniel Freitag. Plenty more in Freitag's photo sets.

(Via we make money not art.)

And more!

That's about it really:- so this blog will be focussed on my MA in Digital Art and technology (whilst the other will remain as my miscellaneous blog about stuff!).